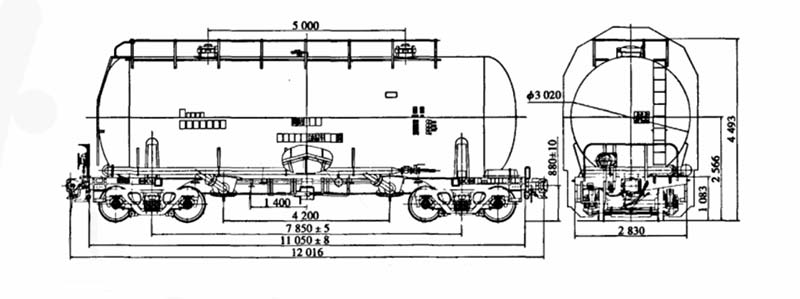

The U70 cement wagon is a type of railway tank wagon specially optimized for the transportation of bulk cement powders. The railway cement tanker is designed to drive on the standard gauge railroads and can load up to 69 metric tons of goods.

Essential Parameters of U70 Cement Wagon

- Loading capacity: 69 t

- Tare weight: 24.8 t

- Axle load: 23.45 t/axle

- Overall length: 12016 mm

- Overall width: 3020 mm

- Overall height: 4493 mm

- Gauge: 1435 mm

- Max speed (full load): 120 km/h

- Minimum radius of curvature negotiable: 145 m

- Load per linear meter: 7.8 t/m

- Tank volume: 58.3 m3

- Tank pressure: 0.35MPa

- Environment Temperature: -40~+50 ℃

- Tank size (length*diameter): 10600mm*3000mm

- Length btw bogie pivot centers: 7850±5 mm

- Fixed wheel base: 1830 mm

- Coupler height: 880±10 mm

- Service life: 25 years

- Maintenance cycle: factory overhaul per 5 years

Design Structure of U70 Cement Wagon

The whole wagon of U70 is composed of the tank, the draft sill assembly, the braking system, the ladder assembly, the air inlet and discharge pipeline assembly, the steering gear, the coupler and buffer, and other accessories.

The Tank

The material used to forge the tank is the Q345GNHL high-strength weather-resistant structural steel. The whole tank is assembled and welded together by a cylinder body and two hemispheric heads. The cylinder plate is 8mm thick, the head plate is 10mm thick, the outer diameter of the tank body is 3020mm, and the total length is 10600mm. The top of the tank body is provided with two feeding ports, one of which is also used as a manhole and is provided with an inner ladder.

The Draft Sill Assembly

This assembly is assembled by draft sill, bolster sill, side sills, and end sills. The draft sill is made of Q450NQR1 hot-rolled steel B, and the side sill is made of 160mm cold-formed steel.

The Ladder Assembly

A ladder is attached on the B end of the wagon for operators to get on and off. The top of the tank is equipped with a full-length walking board and safety guard rail.

The Air Inlet and Discharge Pipeline Assembly

The air inlet and discharge pipeline assembly are composed of the air inlet pipe, discharge pipe, blowing aid pipe, safety valve, butterfly valve, and other parts. Three DN150 butterfly valves are installed on the discharge pipeline. In order to prevent the discharge pipe from blocking, a blowing aid pipe is set at the tail of the discharge pipe, and a check valve and a ball valve are installed between the discharge pipe and the blowing aid pipe.

Coupler and Buffer

The couplers used on U70 railway cement wagons are the 17# couplers whose main parts are made of E-grade cast steel (equal to AAR M201-E) and have great wear resistance and strength.

The buffers used are MT-2 buffers.

The Braking System

The U70 wagon is equipped with a hand brake device and an air brake at the same time, which can complete emergency braking in various emergencies to ensure the safety of the train to the greatest extent.

The air brake assembly includes advanced components such as Type-120 air control valve, 305mm*254mm spinning sealed brake cylinder, 50L auxiliary air cylinder, ST2-250 two-way brake shoe clearance automatic regulator, derailment automatic brake device, and so on.

Bogies

Type K6 bogies are applied on U70 cement wagons.