Limestone is the essential raw material for cement production. For large and medium sized cement plants located far from limestone quarries, railway transportation is the most cost-effective way to obtain limestone. AGICO Group supplies railway hopper wagons that are specially optimized for limestone. Our engineer team can design exclusive limestone hopper wagons according to the clients’ business needs.

K13BK hopper wagons are a type of special railway hopper wagons designed for limestone transportation by CRRC Taiyuan. They are usually used on the railway lines between limestone quarries and cement plants to carry bulk limestone.

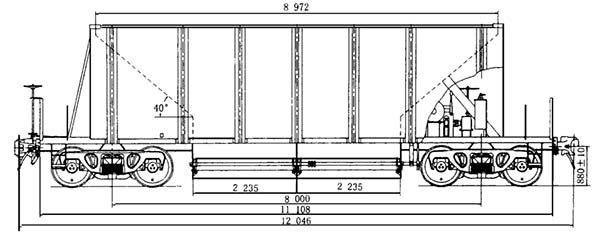

K13BK Hopper Wagon Parameters

- Loading capacity: 60 t

- Tare weight: 21.5 t

- Coefficient of tare weight: 0.358

- Axle: 4 axle

- Axle load: 21 t/axle

- Loading volume: 41 m3

- Gauge: 1435mm

- Hopper inclination: 40°

- Distance btw bogie centers: 8000 mm

- Vehicle length: 12046 mm

- Vehicle maximum width: 3186 mm

- Vehicle maximum height: 3370 mm

- Unloading hatch: 4 (2 on each side)

- Running speed: 120km/h

- Gauge: 1435 mm

- Braking distance (full load): 1189m

- Braking distance (Empty load): 774m

- Minimum radius of curvature negotiable: 145 m

K13BK Limestone Hopper Features

1. The wagon body adopts an all-steel welded structure design; the main bearing components are manufactured with the O8CuPVXt or O9CuPTiRE-A high strength low alloy steel with atmospheric corrosion resistance.

2. The underframe is composed of traction beam, side beam, sleeper beam, end beam, small cross beam, railing, bracket, and steel floor; The traction beam is composed of two 310 Z-shaped steel; The sleeper beam is a steel plate welded box structure.

3. An observation hole is set on the first end wall for the convenience to observe material loading and unloading progress.

4. There are four bottom door discharge ports on both sides of the wagon body. The opening and closing of each bottom door is controlled by a 356 x 280 bidirectional air cylinder and a reducer respectively. The structure design of the transmission device is exquisite and simple. The front and rear supports of the upper transmission shaft adopt the automatic self-aligning rolling bearing, which can avoid the energy waste caused by the non concentric front and rear supports.