The N30 rail flatcar is a 70-ton freight wagon designed by CRRC Taiyuan in 2007. The design gauge of the vehicle is 1435mm, and its maximum driving speed can reach 120km/h. It can be competent for medium and long-distance railway freight transportation.

The N30 rail flatcar is mainly used for railway departments such as power supply and engineering departments to transport materials, pillars, ladder cars, etc. It can be also connected with the engineering operation car to carry out catenary maintenance or emergency repair missions.

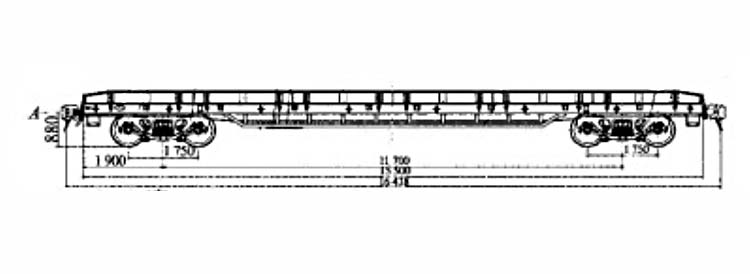

N30 Key Parameters

- Loading capacity: 30 t

- Tare weight: 17.8 t

- Axle load: 21 t/axle

- Distance between bogie centers: 11700mm

- Overall length: 16430 mm

- Maximum width: 3114 mm

- Fixed wheelbase: 1750 mm

- Maximum height: 1452 mm

- Coupler height: 880 mm

- Wheel diameter: 840 mm

- Coefficient of tare weight: 0.61

- Braking rate (empty): 26.9%

- Braking rate (full load): 21.9%

- Environment Temperature: -40℃~+50℃

- Gauge: 1435 mm

- Max speed (full load): 120 km/h

- Minimum radius of curvature negotiable: 145 m

Design of N30 rail flatcar

An N30 flat car is mainly composed of the car body, the coupler buffer device, the braking device, and bogies.

Car Body

The car body is all steel welded, including components such as the underframe, side doors, and end doors.

Underframe: The underframe is the foundation of the whole car; it is composed of a center beam, side beams, sleeper beams, end beams, crossbeams, longitudinal auxiliary beams, and a steel floor.

The center beam is made of a fish web beam, which is assembled and welded by two 450 I-beams into one through the connecting plate. The front and rear slave plate seats are connected with the center beam web with rivets.

The forged upper center plate and welded center plate seat are adopted in this design.

The side beam is composed of two 240mm * 80mm * 9mm channel steels, and each side beam is equipped with column inserts and rope bolts.

The sleeper beam is an I-section structure with web plates and upper and lower cover plates assembled and welded.

The floor adopts 4mm thick lentil pattern steel plates.

Side doors: The N30 flatcar has 4 end-side doors and 8 middle-side doors. The side door is of all steel welded structure, which is composed of side door plate, angle iron, column, etc. The side door hinge is welded on the column. When it is erected, the stop iron of the hinge locks the side door.

End doors: The whole car has 2 end doors. The structure of the end door is similar to that of the side door. The end door can be placed flat when shipping long and large goods. After the end door is leveled, it is supported on the end door support of the end beam of the underframe for use as a transition plate.

Coupler & Buffer Device

The car adopts a grade C steel 13A down acting coupler and supporting coupler yoke, the coupler yoke pin is made of alloy steel. The buffer is type MT-3 buffer.

Braking System

The car adopts an air braking device whose main pipe pressure can meet 500kPa and 600kpa. The main accessories include integral spinning with a diameter of 254mm, sealed brake cylinder, improved ST2-250 two-way brake shoe clearance automatic regulator, KZW-A empty and load automatic regulator, etc.

The car is also equipped with an NSW hand brake to deal with situations requiring manual braking.

Bogies

Type K2 bogies are applied on N30 rail flatcars.