Our company has advanced production lines for railway couplers, which mainly produces 13# and 17# couplers used by domestic freight wagons in China, and can also be customized to produce other couplers according to the drawings provided by clients.

The coupler is a key railway wagon component that connects the wagon with the locomotive or other wagons, and transfers traction force, braking force, and eases longitudinal impact force during the traveling of the train. It consists of a coupler, buffer, coupler yoke, and slave plate, which is installed in the traction beam at the end of the underframe structure.

Ordinary couplers are not closely connected, there is still a certain gap after the coupler is locked. This gap is very important for the train, because when the train stops, due to the speed of the wind pressure signal transmission, there is a certain time difference between the front and rear vehicle braking, which makes the rear vehicle squeeze the front vehicle when braking, making the gap between the couplers empty. When the train starts, due to the existence of the gap, the locomotive will drive the first car first, then the coupler will be tightened and drive the second car, and so on, so as to avoid the train carrying all the cars at one time, because it will put forward higher requirements for the traction of the train.

There is a buffer device between the coupler and the underframe. This buffer device can reduce the impact of braking, starting, and coupling, which is very important to ensure passenger comfort and cargo integrity.

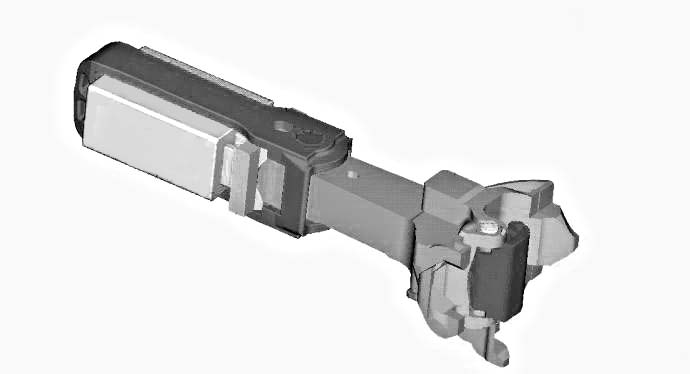

Composition of The 17# Coupler

The coupler buffer device is mainly composed of coupler, buffer, coupler yoke, coupler pin, slave plate, and other parts. The coupler and the coupler yoke are connected as a whole with the help of the coupler tail pin, and the front cluster plate, buffer, and rear cluster plate (sometimes without the rear cluster plate) are installed in the coupler yoke to form the coupler buffer device.

Type 17# Coupler Specifications:

- Effective length of coupler: 735mm

- Length of hook body: 430mm

- Longitudinal movement clearance of coupler connection profile: 9.5mm

- Maximum lateral swing angle of coupler: 13 degrees

- Maximum vertical swing angle of coupler (upward): 5.5 degrees

- Maximum vertical swing angle of coupler (downward): 7 degrees

- Maximum lateral displacement at coupler connecting line: 167mm

- Maximum vertical displacement at coupler connecting line (upward): 71mm

- Maximum vertical displacement at coupler connecting line (downward): 90.5mm

- Maximum relative rotation angle in horizontal plane: 3 ° 45 ‘

- Maximum relative rotation angle in vertical plane: 2 ° 0 ‘

- Allowable height difference of coupler center line when two couplers are connected: 75mm

- Static tensile failure load of hook body: ≥ 4005kn

- Static tensile failure load of knuckle: ≥ 3430kn

- Minimum limit load of coupler yoke: 4005kn

Notable Features of 17# Coupler

1. The small coupling clearance of the coupler can reduce the longitudinal impulse of the train, improve the dynamic performance of the train, improve the safety and reliability of railway freight transport, and extend the service life of the vehicle;

2. The coupler has the function of interlocking and anti-detaching, which can realize the interlocking automatically after the coupler is coupled. The anti-detaching device is set under the coupler head, which can maintain the coupling performance of the coupler in case of a train accident and prevent the train from overturning.

3. Good wear resistance; the 17# coupler is made of high-strength material. The hardness of the coupler body, coupler knuckle, and coupler yoke is HBS241-HBS311. After special heat treatment, the coupler end face and the arc surface behind the coupler pinhole can reach HBS375-HBS476. The contact part between the lower plane of the coupler body and the coupler support seat is also welded with a wear plate, which improves the wear resistance of the coupler body;

4. The structural strength is high; the structure of the 17# coupler is very advanced, and the main parts are made of TB / T2942-E cast steel equivalent to AAR M201-E.

5. The type 17 coupler has an automatic centering function. The rear part of the coupler is equipped with an automatic centering shoulder, which can keep the coupler in a normal position during traveling of the train.